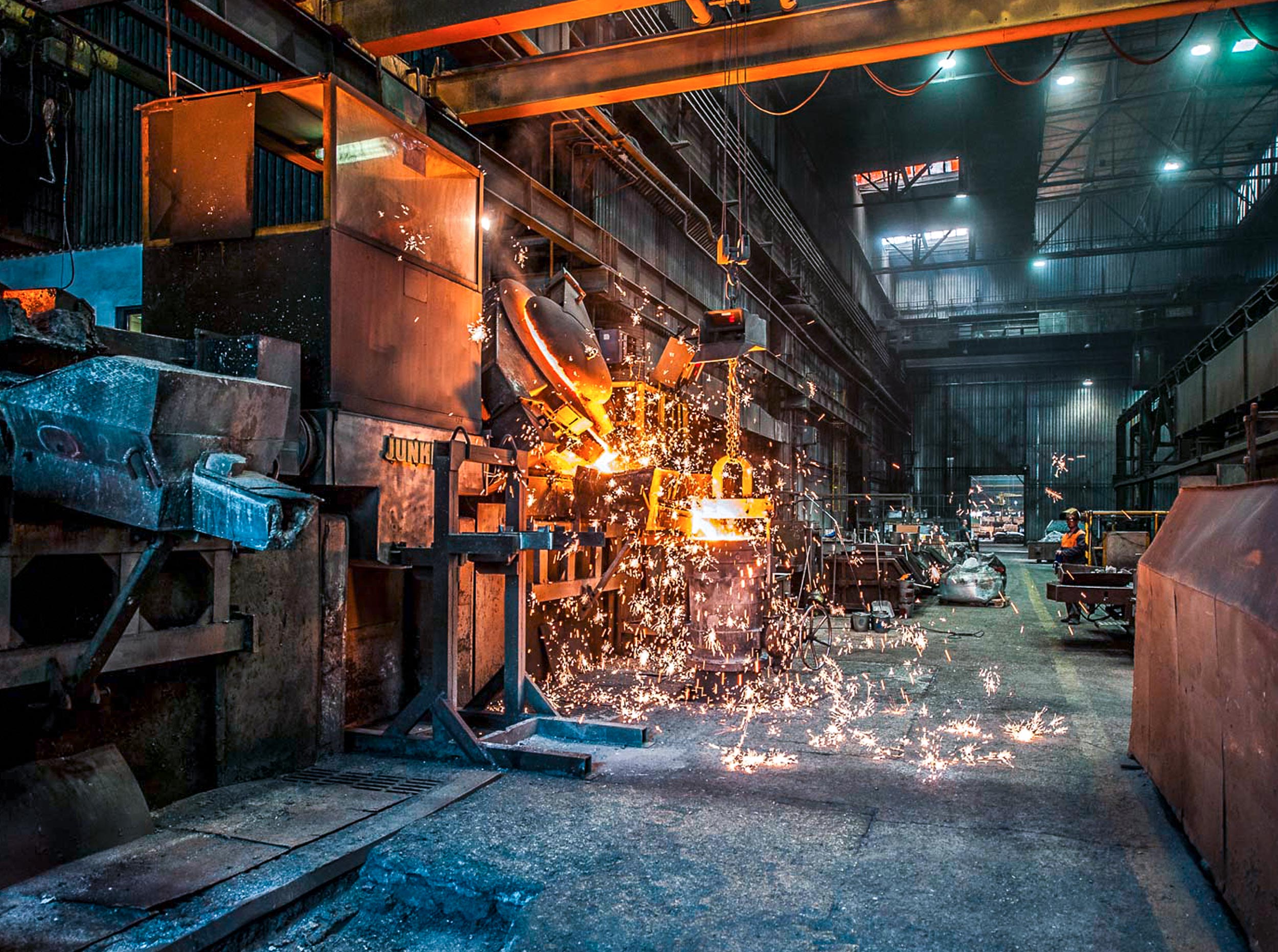

Silbitz now includes four foundries, each with their own product focus. At its headquarters in Silbitz (Thuringia, Germany), various materials based on iron and steel are cast in hand-moulded and automated machine-moulded processes. The castings mainly include parts for engine construction and energy technology. In Zeitz (Saxony-Anhalt, Germany), the company hand-moulds products mainly for wind turbines, such as rotor hubs and machine carriers – usually in small quantities but with heavy unit weights of up to 45 tons. The Torgelow iron foundry, acquired in 2021, can supply even higher unit weights - these products are also mainly used for wind turbines on land and increasingly at sea. This allows the company to participate in the energy transition and in the strong trend towards renewable energy generation. At its fourth production site in Košice (Slovakia), the company uses a range of processes to cast various materials, focusing on highly customised products.

In addition to wind energy technology, Silbitz products are also used, among others, in drive technology (e.g. planetary carriers, bearing housings) and non-automotive engine technology (e.g. in pistons and cylinder covers for marine and train engines). Silbitz supplies its products primarily to customers in Germany, Austria and Switzerland as well as in Scandinavia, with most of its customers being market leader in their respective sectors.

Newsletter

Newsletter

Contact

Contact

Downloads

Downloads